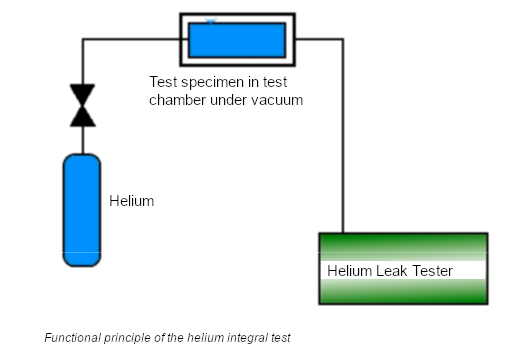

Helium Mass Spectrometry Method: Integral Test

Helium leak testing is the oldest, most sensitive, and most widely used method for trace gas testing. For many gas tightness requirements, this method is the only way to achieve the required accuracies.

Until a few years ago, trace gas detection using mass spectrometers was still very complex, and the sensor technology was extremely expensive. Operating and, above all, maintenance personnel had to be specially trained. However, due to consistent further development and the increasing number of applications, the market now offers a whole range of devices that can be used and operated without extensive training, and whose price has become significantly more affordable today.

Method:

The test specimen is sealed, filled with the test gas under test pressure, and surrounded by a test bell sealed against the environment. The space under the bell is evacuated. As a result, trace amounts of test gas escaping from the test specimen due to leakage spread quickly and evenly. After an enrichment period, a sample of the bell atmosphere is taken and examined for traces of test gas.

Test medium:

Helium (pure or in any mixing ratios with other gases)

detectable leak rates:

>10–10 mbar l/s (>0.000000006 cm³/min)

Advantages

– Extremely small leaks are detectable.

– The test is carried out in an automated testing facility under defined temporal conditions and pressure ratios. As a result, the test results are independent of the diligence of a worker and are more reproducible.

– The temperature and elasticity of the test specimen have no influence on the test result.

– After calibrating the gas concentration / leak rate factor, this method enables a quantifiable leak rate determination.

Disadvantages:

– Very high mechanical effort for the testing device due to extremely high-quality seals under a vacuum-tight test bell. This complicates fault diagnosis in case of sealing problems.

– Risk of test gas contamination in case of incorrect operation, gross leaks, or larger leaks.

– Expensive process and vacuum technology.

– Helium detection takes place under high vacuum, making the process technology very sensitive to dirt and moisture.

Notes:

– Sufficient and complete filling of the test chamber with the test gas must be ensured. The test chamber should therefore first be evacuated and then filled with the test gas.