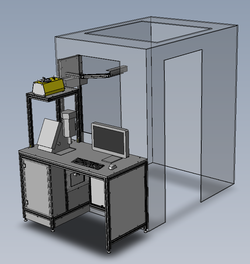

This test station allows to quickly and automatically test filtering half masks during production for the two essential quality characteristics of breathing resistance and filtering capacity in accordance with DIN EN 13274-3, DIN EN 13274-7 and DIN EN 149.

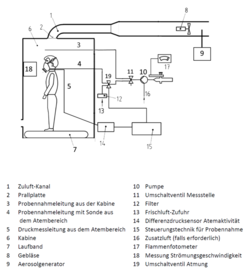

For the test, the mask is clamped into a holder and tested successively for permeability to NaCl aerosol, paraffin oil (PAO) aerosol and for breathing resistance.

For the two types of aerosol, separate generators are used, which are activated during the respective test. For each one, the aerosol concentration is measured both upstream and downstream of the mask. The concentration is measured by means of an optical spectrometer with a measuring range of 0.145-100 µm.

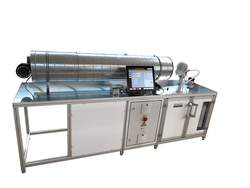

For the measurement of the breathing resistance, the holder with the mask is swivelled by 90° and the measurement is carried out by means of the flow tube specified in the standards. Here, exhalation volume flows of up to 300 l/min and inhalation volume flows of up to 120 l/min are possible.

The test is fully automated and can also be carried out safely by semi-skilled personnel. The test results can be stored locally on a USB flash drive or on a network.