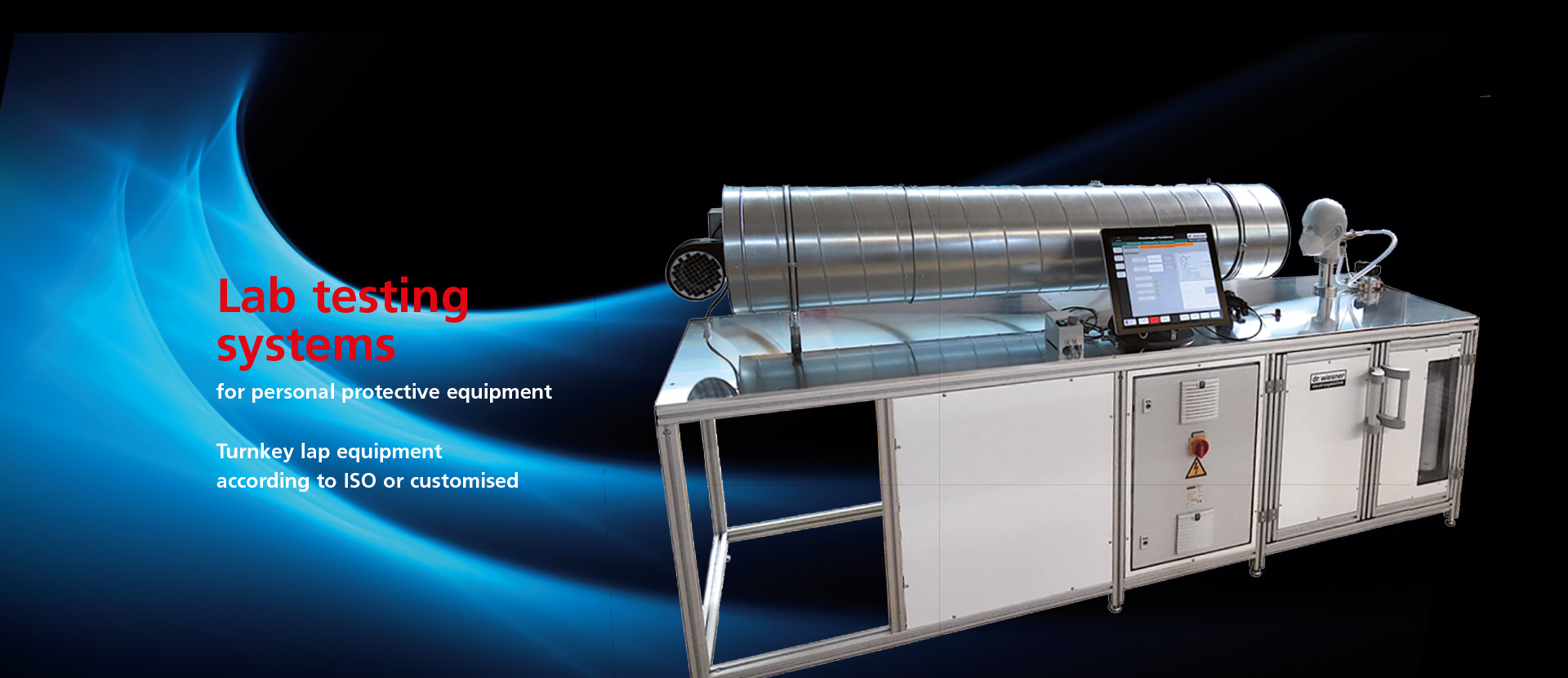

Testing Technology from the Pioneer of Industrial Leakage Testing

As a pioneer in industrial leakage testings the name Dr. Wiesner stands for INNOVATION, QUALITY and RELIABILITY since 1968.

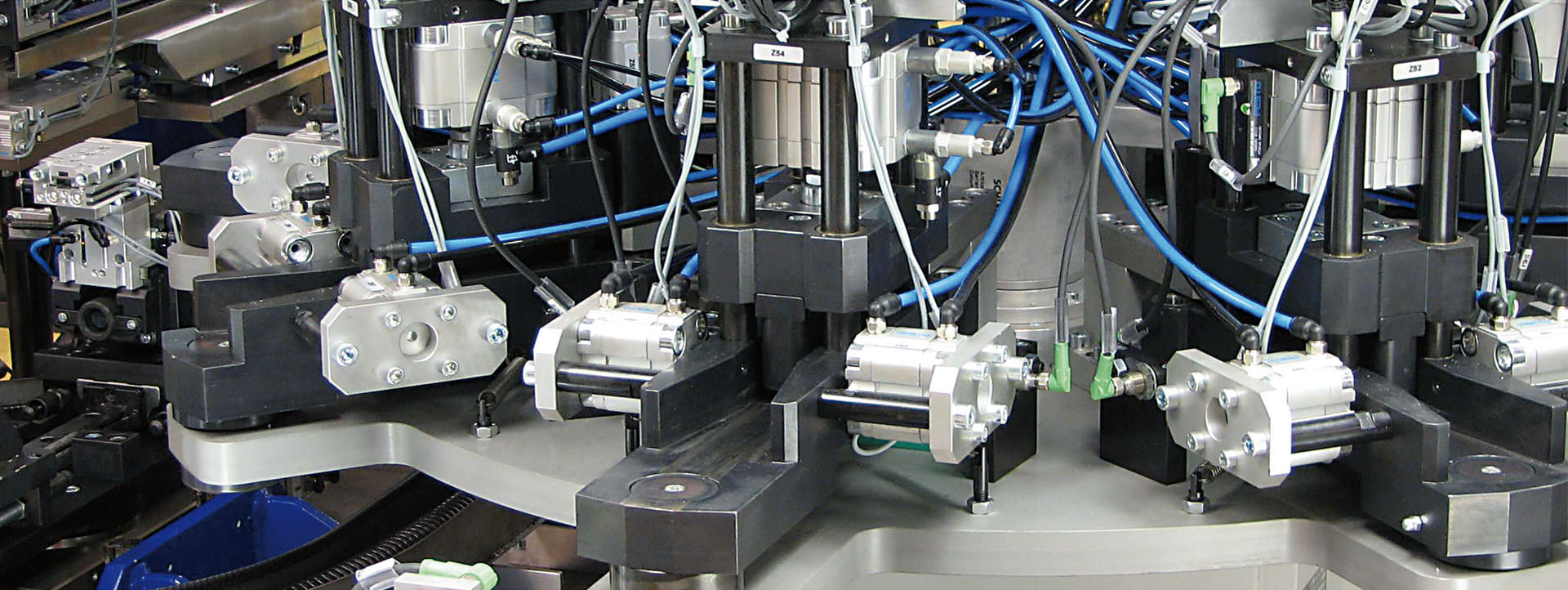

No matter if fully automated, partly automated or manual leakage tests – we provide the suitable solution for every application.

As one of the first companies in the world we were specialized on industrial testings of fluidic measurements, particularly in leakage and flow testings. You will benefit from the best experience from much more than 4000 applications in nearly all branches. References

If the test should be extra fast or with highest accuracy, should it be maximum flexible or optimally tailored to your current application, we will provide the most suitable solution for your requirement.

We're able to use our own products from a great portfolio or we assemble approved products from other established manufacturer as a system integrator. Finally you will get a turnkey system which exactly correlates with your requirement profile - worldwide - timely.

Furthermore we also provide sub-systems which can be integrated in your production line. The installation of the necessary interfaces is understood.

Framed in an advanced scope of services, with us you are in good hands in the field of leakage or flow testings.