Comparative Values for Air Leakage and Notes on the Test Conditions

In leak testing, difficulties repeatedly arise with the metrological description of the term "leak-tight."

In a technical sense, leak-tightness only means "free of leakages according to the technical field of application." Upon closer inspection, the requirements placed on technical systems vary greatly.

The comparative values listed below were compiled from the specifications that we have received from our customers over the course of many years.

We would like to point out that these values are merely general empirical values, which may certainly differ in specific tasks and, if necessary, valid regulations must be observed.

Characteristic | Air leakage | Note | |

from | to | ||

0.5 cm³/min | 12 cm³/min | ||

0.6 cm³/min | 4.5 cm³/min | ||

0.1 cm³/min | 3 cm³/min | Values for liquid fuel | |

0.0006 cm³/min | Current value for USA export |

Whether this leakage is tested with overpressure, with vacuum, or with the aid of gas detection methods usually depends on the operating conditions of the product.

Ideally, the actual operating conditions are taken into account during testing. However, it should be noted that the reproducibility of an air leak test decreases with increasing pressure.

The reason for this lies essentially in thermal processes during filling.

In leak testing with test gas, thermal effects have no influence on the quality of the test result, so that hot or thermally sensitive parts can also be tested without any problems using these methods. Furthermore, constructive features of the test object should be observed. For example, a high test pressure can press an elastic seal in the test object so strongly onto its seat that an existing damage is closed and thus not detected during the test. If this seal hardens due to aging, a leakage can occur at such defects during later operation.

If the test pressure is reduced for the reasons mentioned above, it must be taken into account that the limit value should be tightened accordingly.

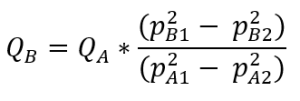

For (compressible) gases, a quadratic relationship applies; for (incompressible) liquids, a linear one.

The following procedure can be used for air:

QA: Flow rate at measurement A

QB: Flow rate at measurement B

pA1: Test pressure at measurement A

pA2: Air pressure at measurement A (typically 1013 mbar)

pB1: Test pressure at measurement B

pB2: Air pressure at measurement B (typically 1013 mbar)

A test object that is to be watertight at 5 bar and for which a limit value of 6 cm3/min has therefore been defined must consequently be tested at a leak rate of 0.5 cm3/min when tested at 1 bar.

Of course, the constructive features presented above must also be taken into account in this determination. When testing hermetically sealed parts from the outside, special attention must be paid to the worst-case scenario of "gross leakage." In such test tasks, the filling process must not be carried out exclusively in a time-controlled manner, as otherwise, in the case of gross leakage, the space behind the leak will already be brought to the test pressure during the filling time and no pressure change can be determined during the measuring time.

No matter what your testing task is, we offer you competent advice with proposed solutions.

If we believe it is necessary, we carry out preliminary tests with your test objects and are also available to you in the product development phase on request.