Sealing Technology

Sealing technology is a particularly knowledge-intensive area within our company. A leak test is only as effective as the seals of the test fixture allow. This requires the use of diverse materials and geometries to achieve an optimal synergy between wear resistance and sealing performance.

This specialized knowledge is one of our key competencies in test bench construction, acquired over several decades through countless applications. Our customers benefit daily from this expertise when utilizing our customized testing equipment.

- Sealing technology as a core competence:

Intensive know-how area where the quality of the leak test depends directly on the fixture seals used. - Materials and geometries:

The combination of a wide variety of materials and shapes ensures an optimal balance between wear resistance and reliable sealing effect. - Many years of experience:

Expertise gained over decades in test bench construction, which benefits our customers daily in customized test equipment.

Marking Unit

Marking unit type 1.110 / 1.116

For marking components made of

steel (type 1.116), aluminum, or plastic (type 1.110)

- Extremely compact design

- With end position monitoring

- Pneumatic pulse triggering, making it significantly less susceptible to wear than mechanical designs

- HSS punch tip

- Any installation position

| Variants | Marking material | Dimensions (WxHxL) |

| Type 1.110 | Aluminum, plastic | 32 x 32 x 140 mm |

| Type 1.116 | Steel | 32 x 32 x 160 mm |

- Product: Pneumatic impact cylinder (part number 1.110.999.3.0)

- Stamp stroke: 15 mm

- Air connection: M5

Sheffield Test Head

Sheffield test head according to DIN EN 149

for performing various breathing resistance tests

or for determining the carbon dioxide content of inhaled air, e.g., according to

- DIN EN 149 Clause 8.7, Clause 8.9.2 and Clause 8.9.3 or

- DIN EN 13274 Clause 7.3.2 and Clause 7.3.3

Stand tiltable by 90°:

- forward, backward,

- left, right

- Standards: DIN EN 149, DIN EN 13274

- Concentric suction, pressure, and measuring tube

- 4-way tiltable stand (90° in all directions)

- Hose connections: NW15 (Inhalation/Exhalation), NW4 (Pressure measurement)

- made from environmentally friendly PLA

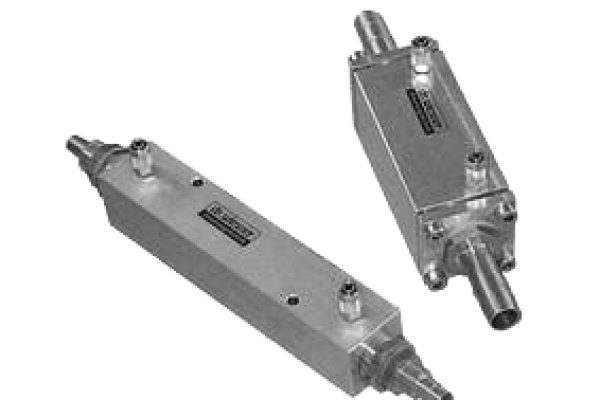

INTEGRA Additional Test Circuit

INTEGRA additional test circuits are used when several test objects are to be tested simultaneously, several test circuits in one test object are to be tested simultaneously, or several tests are to be carried out completely independently of one another in one system. Up to two additional test circuits can be connected to each INTEGRA or INTEGRA evo leak testing system with the aid of the optionally available multi-circuit expansion, so that three different tests can be carried out per leak testing system. All test circuits operate completely independently of each other. They can use different or the same parameter set, they can be started simultaneously or one after the other, and each test circuit can operate according to a different test method. Test circuits for customer-specific special applications for additional, e.g. function tests are also possible.

- Expansion by up to two additional test circuits for INTEGRA and INTEGRA evo

- All test circuits operate completely independently of each other

- Different parameters, test methods, and start times are possible

- Can also be used for customer-specific special and functional tests

Vacuum Station

(Part No. 1647) for testing according to DIN EN 149, DIN EN 13274-3 and CWA 17553

- 2x rotary vane vacuum pump with K-Motor IP54

- Pumping speed: Air flow per pump approx. 10m³/h against 0 bar

- Ultimate vacuum: -850 mbar rel. / 150 mbar abs.

- “CompactAir” housing system with pull-out handle and robust rollers

- Front cover in aluminum according to RAL 7015, essential frame parts made of aluminum

- Additional 230V socket on the rear

- Internal vacuum filter and exhaust silencer.

Remote Control

- for INTEGRA or INTEGRA evo

- Program selection 1-16

- Start

- Stop

- Acknowledge

- Indicators for result display